Clara Matynka, our CAMZ, took a sewing class in school, either in 8th grade (1943) or 9th grade (1944.) Her class notes, after sixty years in attics, shall now be largely on the internet so her grandchildren can see them. This is known in biology as "alternation of generations." What it is called in family life, I cannot say.

Now you must attend and understand, Best Beloved, that "Gittere" is pronounced "GIT-tree." This is as in:

"Hey, where we having Thanksgiving dinner?"

"On Gittere, hey."

Look at this! Clara scored 99 out of 100 points for quality of workmanship in her dressmaking project. Then Mrs. Landsman deducted 12 points for lateness! Matka Boska!

I class Mrs. Landsman with my own Mrs. Merrill, about whom I shall say no more.

Then came the study of the cartography, or surgical anatomy, of garment patterns.

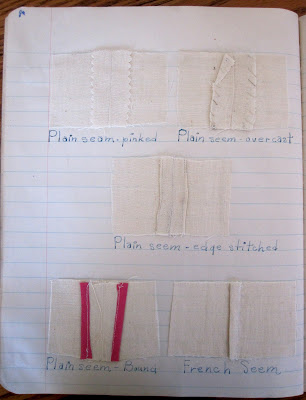

Then came practice in suture patterns, in a big section named "Seams."

The instructor did not just say "There are many kinds of seams," nor did she make them watch movies that just said the same thing, like my own teacher did a generation later. The students sewed each kind, and turned in a sample of each kind. Any subject can be approached in slacker mode, or with rigor.

|

| Hem at the top; double and single lines of stiching; at the bottom, hand-basting of ravel edge. |

|

| Plain seam, pinked; Plain seam, overcast; Plain seam, edge stitched; Plain seam, "bound" with "seam binding"; French seam. |

|

| Add caption |

|

| Fell seam; Mock French; Lapped seam. |

"Lesson 6: Bias" explains in plain language what I have never heard, nor intuited for myself: how flat cloth can be made to fit a curved, three-dimensional human body.

"Material is woven of two threads:

1. Lengthwise or warp (stronger thread)

2. Crosswise or woof (weaker thread)

A bias is cut diagonally across these two threads.

The advantage of using a bias is that it stretches and fits around a curved edge making a flat smooth finish."

These four hand-worked buttonholes were graded at 80%.

Next time, having considered mechanics, we shall proceed to aesthetics.

No comments:

Post a Comment